NDT Products

Our Products

Remote Visual Testing

Video Borescope VH2

Bscope Rugged Waterproof Videoscope

Rigid Borescopes & Fiberscopes

Borescope With Camera

Eddy Current Testing

Eddy Current Conductivity Meter

Eddy Current Test Blocks

Other Solutions

Portable Hardness Testers

Mobility:

In comparison with stationary table-top devices and testing devices with an internal sensor, using the SAUTER HMO. offers the highest level of mobility and flexibility

All measurement directions possible (360°)thanks to an automatic compensation function

USB interfacefor connection to the printer and charging the batteries.

Precision: 1 % 800 HLD (± 6 HLD)

- Measuring range tensile strength: 375–2639 MPa (steel)

- Min. sample weight on a solid and stable support: Sensor D + DC: 3 kg Sensor G: 15 kg

- Minimum sample material thickness:Sensor D + DC: 8 mm Sensor G: 10 mm

Minimum sample radius (concave/convex): 50 mm (with support ring: 10 mm)

Dimensions W×D×H 83×24×135 mm

Operation by rechargeable battery pack, operating time up to 50 h, mains adapter included, can be reordered,

Net weight approx. 228 g

Compatible Hardness Testers

Woodpecker WP632AM-R

The WP632AM-R is compact and lightweight allowing single handed operation and significantly reduces time required for inspection with high accuracy.

The WP632AM-R has been recognized as authorized NDT equipment by Airbus and Bombardier Aerospace. The WP632AM-R is also codified with the NATO Stock Number 6635-99-282-4319.

Thermography Cameras

Ferrite Meter

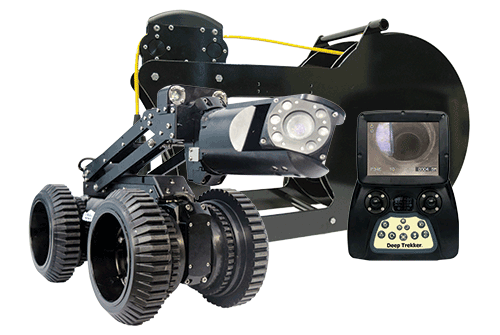

DT640 Utility Crawler

utility crawler to maneuver in tight areas and tough surfaces. Rare earth magnets allow the DT640Mag to climb in almost any direction on ferrous materials.Contact us today to order your Utility Crawler and start expanding your inspection capabilities now.

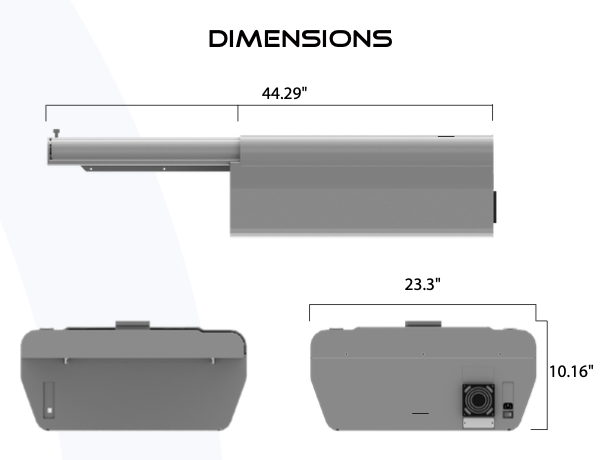

NDT CR(Computed Radiography) Digital Industrial Scanner

- 25 Micron Resolution

- 16 Bits/65536 Shades of Grey

- True Flat Bed Scan Path Process

- DICONDE Compliant

- OS-Windows 7,8,10-64 Bit

Wire Rope Tester

Wire Ropes Diagnostic System can help to increase the safety and lifetime of wire ropes.

Wire Rope Diagnostic System enables detecting long changes in the rope cross-section due to corrosion and wear (LMA sensor) and local changes, e.g. broken wires, corrosion pitting and other local rope damage (LF sensor). The inspection results are said to be reliable, accurate and repeatable.

Ultrasonic Testing

Thickness Gauges

Ultrasonic Flaw Detector

TOFD & Phase Array Equipment’s

UT Accessories

Adapters

UT cables

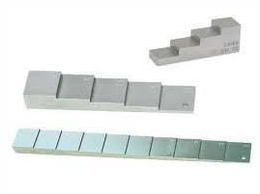

Step wedge (CS - SS)

V1 block

Ultrasonic probes